How to make a dog house out of foam plastic. How to make a warm booth for a dog with your own hands

The owners of private houses try to make every effort to make it cozy and warm during the cold season. But what about the dog that guards the yard and the owners? The booth in which the pet lives also needs thermal insulation. From our article you will learn how to insulate a dog house for the winter.

Everyone freezes in winter. And this applies not only to people. Even long-haired dogs feel uncomfortable and chilly. Especially if the kennel is not insulated and not ready for winter. You should definitely take care of creating the proper conditions for the animal in advance.

Taking a dog into a house that is constantly on the street is not the best option. The animal may feel uncomfortable. The dog may ask to go outside, tear things, spoil furniture and even show aggression. In order for everyone to be comfortable and familiar, it is necessary to prepare the booth in advance, protecting it from rain and cold.

Video "Building a warm dog house with your own hands"

From this video you will learn how to build a warm booth for a dog with your own hands.

General rules

There are a number of rules and requirements that must be observed:

- It is better to position the booth so that the entrance is located in a calm - with minimal wind movement.

- The ideal option is a kennel made of wood.

- To eliminate the risk of rain or melt water, you can use one of two options: make high-quality insulation or place the kennel on a hill.

- The dimensions of the booth should correspond to the size of the dog. The main thing is that the animal does not crowd there.

- It is better to put the kennel not in continuous shade, and not in the open sun. Choose the golden mean.

- It is important to repair the roof in time to prevent leaks.

What material to choose

The owner has a lot different materials, each of which guarantees good thermal insulation and neat appearance kennels.

mineral wool

Mineral wool leads among other materials in terms of technical characteristics. She needs to be handled very carefully. Fiber negatively affects the health of the animal. Wherever the owner uses it - inside or outside the booth - the layer must be covered with a cladding. Don't forget about waterproofing.

When using mineral wool, thermal insulation resembles a layer cake:

- wall of a dog house made of wood;

- polymer film that protects against moisture;

- layer mineral wool;

- membrane;

- outer cladding.

As for the ceiling and floor, they will also be insulated with several layers.

Styrofoam

Styrofoam is another very popular material that is presented on the current market. It is not affected by moisture and does not contain dust. Mounting the structure is not difficult. By the way, branded mineral wool is many times more expensive than polystyrene.

The material is versatile. It is used and placed on the walls and floor of the booth. They also insulate the kennel from the outside. If the owner of the dog settled on this option, additional waterproofing is not needed. A facing material can be easily applied to the insulation layer.

As a rule, insulation work occurs as follows:

- measurements are taken and foam is cut out;

- insulation material is fixed with a special adhesive foam;

- cladding is installed.

Felt

This material is natural. It is inexpensive, and guarantees complete safety. Felt is an ideal material for warming a dog kennel.

Among its characteristics is vapor impermeability. This means that the booth will always be dry. The material is also not blown, so it is not necessary to close it. If desired, you can fix the insulation layer with ordinary nails with large caps.

liquid insulation

An alternative to the options proposed above is a liquid insulation that will protect the animal from the cold. In appearance, the material resembles foam, after spraying it solidifies. When choosing a liquid insulation, remember that the layer must be at least 5 cm. The material has shown good wear resistance, and "promises" 30 years of service. Cured foam does not absorb moisture and steam. At the same time, after applying a layer of liquid insulation, lining is simply necessary.

Warming technique

Each of the above materials has its own characteristics. Speaking about the technique of warming a dog kennel, it is important to remember the following rules:

Among the advantages of a collapsible booth are:

- ease of repair - a dog can gnaw a manhole, and then the owner dismantles the damaged elements, changes the damaged boards and fastens new parts again;

- ease of manufacture - the kennel is manufactured in an equipped and convenient location, after which it can be easily transferred to the yard and quickly installed;

- ease of cleaning - in order to completely disinfect the dog's home, the owner must completely disassemble it, carry out all the work, and assemble it again.

Non-separable booth

- No possibility of blowing. In a non-separable booth there are no places where its elements are joined. The same can be said about the absence of micro-slits, because the floor and walls come together.

- No draft. Dogs tolerate it much worse than frost. So the dog will be protected from the constant wind flow, will not catch a cold and get sick.

- The corners of the kennel have the maximum continuous thickness of the wooden layer.

- All elements are rigidly connected. This is a guarantee of durability and reliability of the booth. The owner will also not need to periodically tighten the connecting fasteners, which is extremely important in collapsible kennels.

Alternative Methods

Sometimes, while looking for an alternative way to warm the booth, the owners use bold, but ineffective methods:

- Heating the kennel with a light bulb. The heating lamp can create the desired temperature. But do not forget that the dog can burn or overheat due to a hot device. 50 cm is the minimum distance that must be between the device and the animal. Given the size of the standard booths, it would not be easy to enforce such a rule.

- Autonomous heater. Often runs on batteries. There are models that resemble heating pads. Their filling allows you to retain heat for a long time. In order for the device to work well and generate heat, it must be heated. Using a battery-operated heating pad, the owner connects it to the main heating complex as an addition.

electric heater

The simplest and most popular method among dog owners is the installation of a panel electric heater. Infrared panels, powered by electricity, maintain the optimum temperature inside dog kennel. In this case, the owner does not bear special costs for insulation and electricity. The system attracts with such advantages:

no noise during operation;

- small-sized equipment (2 cm - standard thickness);

- the air is heated no higher than 50 ° C, moderate heating does not dry out the air, so it is not necessary to cover the heater with a wooden grate;

- ease of installation - it is enough for the owner to fix the electrical panel with self-tapping screws on the desired surface;

- fire-fighting characteristics - it is possible to use the panel constantly during the day, while there is no need to monitor the booth.

IR film

Used to insulate booths infrared film. This is an ultra-thin heater that accumulates heat by emitting IR waves.

The heating element distributes heat, so the animal will definitely not overheat.

The film heater consists of three components:

- heating element - necessary for conversion electrical energy in thermal;

- foil - needed so that the heat evenly diverges throughout the kennel;

- laminated film - guarantees excellent insulation and protects all components of the system inside from mechanical damage.

A dog house insulated with such a system has the following advantages:

- electricity is used economically;

- the output is healthy heating, which has a positive effect on immune system animal;

- good level of heat transfer - uniform distribution of heat contributes to the fact that there are no "cold zones";

- the air humidity in the kennel remains unchanged.

Pick up best option, and insulate the home for your pet in advance!

Good day readers and guests of the site.

Today we'll talk about how and how to insulate a booth for a dog, we will consider in detail the types of heaters and the main points of warming the booth for your pet.

To build or not to build a booth for a dog, I think it is pointless to argue, but whether to insulate it, opinions differ here. Someone believes that the dog is not afraid of frost, so warming is a waste of time and effort, especially since the accumulated heat will still go through the hole. Others are inclined to believe that the dog is much more comfortable in a “warm” booth, especially in winter. Here, as they say, it's up to you, the dog will not be able to express his opinion.

How to insulate a doghouse.

So, how to insulate the booth?

Ideally, when building a dog house, it is better to use only environmentally friendly materials, such as wood. But what about the heater, because modern world offers it in a wide variety, and manufacturing technology involves the use of various kinds of chemical substances. Although the manufacturers of these products ironically declare the safety of such building materials for all living things.

For a dog house, the following heaters are used:

artificial felt- Made from polypropylene. Keeps heat well. This felt upholstered the inner surface of the house.

artificial felt- Made from polypropylene. Keeps heat well. This felt upholstered the inner surface of the house.

Styrofoam - is a foamed plastic mass, has high heat and sound insulation properties, is not subject to decay. It is actively used in the insulation of houses. There is a debate about the dangers and dangers of polystyrene foam. Since it is made on the basis of polystyrene containing residual styrene - a strong toxic substance that adversely affects a living organism. Styrofoam manufacturers claim that the content of residual styrene in polystyrene is not high (within 0.01-0.05%), which guarantees the safety of the foam.

Penoplex - represents a new generation of thermal insulation materials. Produced in the form of plates. The main advantages of the material: low thermal conductivity, does not get wet, does not rot.

Mineral wool- this is a fibrous heat-insulating material obtained by melting silicate rocks, metallurgical slags and their mixtures. It has high heat and sound insulation properties, is non-flammable and moisture resistant.

Mineral wool- this is a fibrous heat-insulating material obtained by melting silicate rocks, metallurgical slags and their mixtures. It has high heat and sound insulation properties, is non-flammable and moisture resistant.

In addition to traditional methods of insulation, there are various kinds of forced insulation - heaters.

In addition to traditional methods of insulation, there are various kinds of forced insulation - heaters.

- Panel heaters- are electric infrared panels in a metal case. They are 2 cm thick and do not take up much space. The maximum heating is 45 - 50 degrees. This heater is mounted on self-tapping screws inside the booth, or hidden in a frame under the skin, the wire is led through a small hole to the outlet.

- Film heaters — are thermal films that work on the basis of infrared radiation. Maximum heating 60 degrees. Mounted under the inner lining of the building.

How to insulate a doghouse.

Usually all parts of the booth are insulated - the floor, walls, roof.

When assembling, it is necessary to ensure that there are no slots and through gaps between the joints, I wrote more about this.

The insulation is inserted into the frame under the outer skin and closed from the inside with sheathing material. Such material can be plywood, oriented strand board OSB, lining, etc. Fiberboard and chipboard are highly undesirable. The inner lining should fit snugly against the frame and completely cover the entire surface of the applied insulation.

Since plywood tends to delaminate, to prevent this, I advise you to nail around the entire perimeter of the booth, as well as in the corners - a semicircular glazing bead.

Curtain for booth.

For better heat retention in the cold season, the hole is covered with a curtain made of heavy and coarse fabric (for example, tarpaulin, artificial felt, etc.), while the size of the curtain should be such that it covers the entrance as much as possible. To do this, we measure the laz , add 5 cm from the side, and 10 cm from the bottom, mode into identical strips along the height, without cutting to the end, hang with a wooden plank and self-tapping screws from the outer or inside booths.

And here is the second version of the manufacture of curtains for the manhole.

And here is the second version of the manufacture of curtains for the manhole.

In order for the dog to endure the cold season more comfortably, a litter of dry straw or hay is arranged in the booth. It is advisable to change the bedding once a week, while shaking it daily to remove debris.

And in conclusion, I would like to say that not one insulated booth will save the dog from the cold in severe frost, so it is recommended to keep your pet in a warm room for this period. In less severe periods, the dog can easily get by with a booth, especially if it is insulated.

P.S. In the next article I will tell you in detail how to make an insulated booth for a dog. Not to be missed

Winter is a difficult time for both people and animals. But it's not easy if you're not prepared. If the necessary measures are taken in time, both people and pets will be comfortable. Since more often than not there is a dog in the household, insulating the dog house will be the first important step in preparing for winter.

Photo of an insulated booth

There are different opinions about whether a doghouse needs to be insulated. Some cynologists argue that only smooth-haired dog breeds need a warm kennel. There are those who offer only hay on the floor of the kennel as a heater. And yet, it is worth considering that our pets live in different regions. This may be the Leningrad region, and sunny Crimea. And with the latest climatic estates, even winters in primordially warm regions can be cold. So, if you think insulation is necessary, how to carry it out?

Warming approaches

Let's single out four main approaches to how to insulate a booth for a dog:

- Floor insulation with hay;

- Use of a curtain;

- Creation of a vestibule;

- Integrated insulation.

The choice of approach depends on three factors: the region in which the owner lives with the pet, financial possibilities and, of course, the attitude towards the dog. Apparently, you definitely have the latter, since you are looking for information about the insulation of the kennel.

Hay on the floor

- Price. Hay should be changed regularly (at least once a season). It takes money and time to buy.

- Fleas. Some argue that fleas can start in hay. But, if you regularly change the flooring, this will not happen. By the way, your dog will be happy to help with this, regularly pulling the flooring out of the booth in parts.

Of the advantages, the highest environmental friendliness can be noted. This type of insulation is most similar to the natural habitat of the animal and will definitely appeal to him. Some owners buy hay from pet stores, such as hay for rabbits. Others prefer a more economical version of their own harvesting.

blind

The shutter is attached to protect the main source of heat leakage - the manhole. If this particular structural element is not well protected, many other insulation actions will not make much sense. What material to choose for curtains?

Some breeds of dogs do not like curtains. For example, these include German Shepherds.

Precisely durable because the dog will inevitably play with it. The curtain needs to be replaced from time to time, so there is no point in using too expensive fabric either. Most often, the canopy is made from an old bedspread, which is available on the farm. In online stores you can buy a silicone curtain at a price of 400-500 rubles.

Tambour

The tambour or "hallway" will significantly insulate the dog's home. This method of thermal insulation does not exclude the possibility of hanging a curtain, but even if there is none, it will be effective. With the correct structure, the hole into the booth and the hole from the vestibule into the main part of the booth should not coincide. A tambour, done correctly, will be a buffer zone that does not allow warm air to escape from the kennel.

All of the above are mediocre methods of insulation and are suitable for warm winters and / or temporary insulation. If the winter is going to be cold, and you want to insulate the doghouse for many years, you need to take comprehensive measures.

Complex thermal insulation

Immediately it is worth mentioning that you can buy a home for a dog. Such an insulated booth for a dog will cost from 5 to 30 thousand rubles. The price depends on the size and material. However, if you want to make a warm house for a dog with your own hands, detailed instructions find further.

The choice of insulation for the kennel

How to insulate a dog house? Most often, dog houses are insulated with foam. This material is relatively inexpensive. If you look in the pantry of many households, you can even find scraps left after the owners themselves have been insulated. In some cases, the material is enough. Mineral wool is also used, although less frequently. Such a heater is considered breathable and in the summer it will create less problems pet. Also, sprayed polyurethane foam can be used. However, this is rather an expensive exotic, although its application is technically simpler than the same foam.

Let's take a look at the most popular budget option- polystyrene. It is worth saying about mineral wool: if you decide to use it for a kennel, be sure to cover the plates with a vapor barrier layer. In this case, the insulation will be protected from moisture and the fibers will not harm the pet.

Making a frame

If the booth is already ready to be insulated with foam plastic, you need to make a kind of crate by attaching a beam to the walls. In the voids formed, we will lay the foam. The rails are fastened on the inside with self-tapping screws. A similar crate is made on the floor and on a removable roof.

If the roof is fixed, especially pitched, it is best to redo it. A non-separable roof will not make it possible to maintain cleanliness in the kennel. In addition, dogs love to climb on their homes.

After preparing the crate with a construction knife or other tools, we cut out the necessary pieces of foam.

The foam should be 5-10 mm wider than the prepared niche for it. In this case, the material will be tightly fixed.

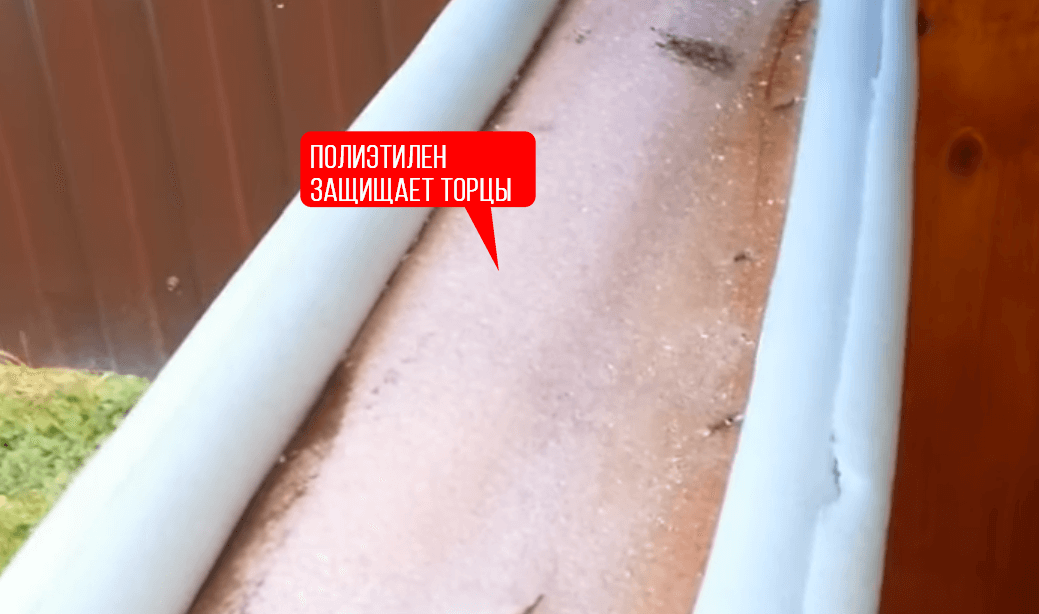

Having thus insulated the floor, ceiling and roof of the booth, we have done most of necessary work. Some owners make windscreens on top of foam sheets. For example, polyethylene can be used.

This approach will also help protect the upper ends of the insulation from moisture.

Now it remains to close the foam sheets from the outside.

Finishing

We close the foam sheets with a board or decorative elements, for example, under a beam. Do not leave the foam in the open air, because the sun and moisture will greatly damage it. And the dog himself will not be indifferent to the heater. The roof is covered with tiles, a sheet of slate, sometimes with linoleum.

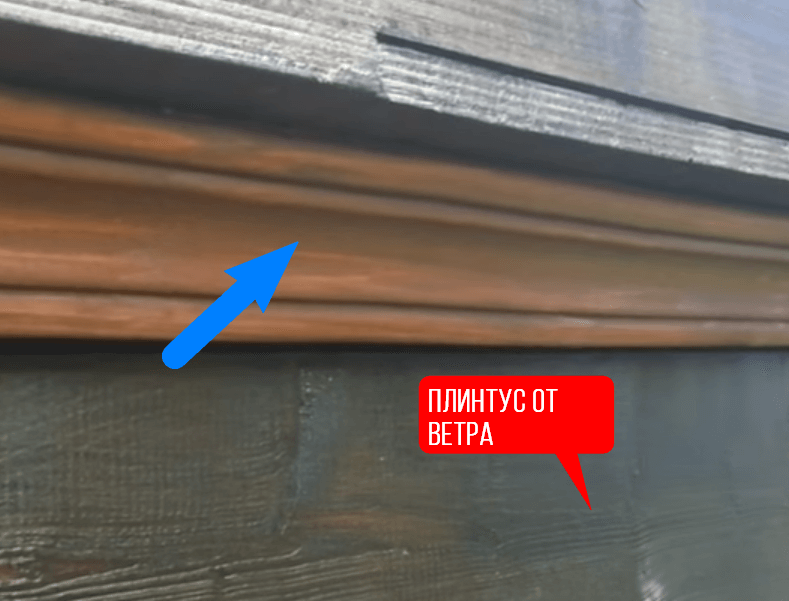

It is also important to take care of the cracks. Pre-blow them well with mounting foam. Also in our example, a plinth is used, which prevents snow and wind from blowing in.

Useful little things

There is no definite answer to the question: should the booth be painted inside or leave the plywood and boards as they are. Dog breeders claim that the paint could harm the health of animals. But, without paintwork, the booth will become unusable in a few years. This moment is up to you.

It is also good if the booth does not stand on the ground, but is raised, for example, you can substitute a few bricks.

Heating in the booth: isn't it too much?

Well, that's how to say. For example, back in 2012, ClimateRight offered a dog kennel air conditioner. So, heating is not a luxury, but quite a necessity. Seriously, the opportunity is there and it is not so expensive. Although, most likely this approach will be useful only for the coldest regions. How to make heating in the booth?

You can make a heating system using the "warm floor" technology. This approach requires pouring the base. To create an electric underfloor heating you need:

- Pour the first layer of screed;

- Lay a layer of foam;

- Lay an electrical cable;

- Pour the cable with a second layer of screed.

Of course, this approach is quite expensive, but it would also be wrong not to mention its existence.

Video: how to make heating in a kennel

conclusions

A do-it-yourself dog house is an inexpensive pleasure. We dismantled the insulation dog house on the example of polystyrene and identified ways to protect the insulation. By applying the recommendations from this article, you will greatly facilitate the life of your furry friend.

How to insulate a dog house for the winter?

In the article, we will analyze the options for performing thermal insulation and try to select materials that will provide warmth to your pet at minimal cost.

Basic principles

Do you need insulation

Let's start from afar - with arguments about whether a dog needs insulation in principle.

On the one hand, wild relatives of domestic dogs - wolves do not look for a warm shelter for the winter, even in severe cold. A typical wolf's lair is a pit, somehow covered with spruce branches or located under an eversion. Yes, after a heavy snowfall, it is comparatively well sheltered from frost and bad weather; however, when looking for shelter, the wolf does not pick up too much shelter for itself.

Caring for your pet, who guards the house, is understandable. However, does it need to create greenhouse conditions for it?

In the humble opinion of the author, warming the booth for a dog is desirable only if you have a short-haired or smooth-haired breed. Dogs with long hair perfectly adapt to the cold: they quickly grow a thick undercoat, thanks to which the dog sleeps well on bare snow.

The booth is an excellent shelter in case of rain and strong winds. However, a dog that lives in the cold is in most cases healthier than a pet.

However: in extremely severe frosts, dogs are usually just allowed into the house.

Remember the proverb about bad weather and a good host?

insulation requirements

When deciding how to insulate a booth for a dog, you need to remember: we are dealing with an animal that obeys, first of all, its instincts. You can’t explain to the beast that you don’t need to tear the rug on the floor, gnaw at the canopy at the entrance and claw at the foam on the walls.

- Insulated dog kennels should not have internal or external walls that are easily damaged.. Styrofoam padding on the floor or Styrofoam interior lining is not an option.

- Any mineral wool insulation must be reliably isolated from the internal volume of the booth. Rock wool fibers irritate human organs breathing - what can we say about a sensitive dog nose! And they will rise into the air with any strong shaking.

- Pole is a good idea. But it must be dense and very durable: the dog will surely play with it. Considering the grip strength of guard dogs, a tarp or insulated vinyl will not last long.

Such a curtain will reduce heat loss, but it will not last long.

- It is desirable that the heat-insulating material be natural or emit in environment as few harmful substances as possible.

Electric heating

It is possible. We will not discuss its expediency: if it is possible to supply power to the booth, it is quite possible to make it heated.

The advantages of this solution are obvious:

- Even in severe frost in the booth, the temperature will be quite comfortable.

- More importantly, it will always be dry there.

Please note: among other things, this means the absence of mold.

A dog, like any other living being, exhales humidified air, which will condense on cold surfaces. In a warm booth, you can forget about this problem.

The cost of electricity will be more than small: with an area of a square meter, a warm floor will require no more than two hundred watts of electrical power.

What's the catch?

There are two problems:

- Dog activity. If the heating elements are not protected absolutely reliably, sooner or later a situation will arise when the dog scratches the floor or walls and gets to them.

- Don't forget about humidity too. Yes, underfloor heating film tires are protected with bituminous stickers; however, in a pool of water, a short circuit is still theoretically possible. As a result, we will get not an insulated dog house, but a delayed action portable electric chair.

Where will the water come from if the booth is thermally insulated and heated? There are a lot of options - from snow brought on its paws to a situation where a sick or frightened dog forgot where the nearest tree is.

- As a heat source, you should choose not a film heater, but a heating cable. It has reliable protection against short circuits along the entire length.

The cable is also well protected from accidental damage. But it is still better to hide it from the dog.

- If the heating element is placed on the floor, it is better not to be lazy and fill in the screed. Since it is pointless to warm the soil, the screed is poured over the laid foam. Of course, sleeping on concrete is a dubious pleasure, so it is better to lay a sheet of thin felt on top.

- When laying in the walls, the heating cable is protected by plywood or other durable material. Yes, in this case, a significant part of the heat will be absorbed by the gasket, but the alternatives are simply dangerous.

Thermal insulation options

So, how to insulate a dog house? Let's look at several options of varying complexity.

Felt

In terms of time and money, this option is the easiest and cheapest.

It can be implemented with your own hands in just a couple of hours.

- Mats are cut out of thick felt according to the size of the walls, roof and floor. For cutting, a regular sharp knife is used.

- They are fastened inside the booth with the roof removed with ordinary roofing nails with wide hats.

- The roof is in place.

What is the result? We get a fairly effective insulation that will not be blown by the wind. The material is environmentally friendly and will not harm the health of our pet. What is no less important - it has good vapor permeability: there will be no dampness in the booth.

Mineral wool

Let's be honest: its use is rather doubtful. The design will turn out to be quite complex; in addition, for the sake of high-quality insulation, the walls will have to be made very thick.

How to insulate a dog house with mineral wool?

The instruction for thermal insulation work itself is familiar to anyone who has ever performed insulation of a loggia or balcony with the help of this heater:

- The walls are covered with a vapor barrier, which is attached with a stapler.

- On the walls around the perimeter of each, a crate is stuffed from a bar of 50x50 millimeters.

- Mineral wool mats are cut to size with a knife and inserted into the crate, after which the second sheet of vapor barrier is hemmed with a stapler.

- Outside, along the crate, the booth is sewn up with plywood, OSB or wooden clapboard.

Styrofoam

Against the background of the previous insulation, the foam has several noticeable advantages:

- It provides the same effective thermal insulation with less thickness.

- Styrofoam does not cake and does not get wet (therefore, it is often used to insulate balconies). Its heat-insulating qualities do not deteriorate over time.

How to insulate a dog house for the winter with foam? Minus unnecessary vapor barrier - just like mineral wool.

However: you can get by with a much smaller thickness - from 2 to 4 centimeters.

Against the background of heat loss through the manhole, the difference with a thicker insulation will not be felt.

Along with home-made designs, already insulated dog houses can be found on sale. In most cases, it is the foam that is used in them, laid between the two walls of the lining. To look at such a product is quite informative.

Roll insulation

Let's be realistic: with an open hole, thermal insulation will not significantly affect the temperature in the booth. It is much more reasonable not to increase the thickness of the walls, but to reliably protect the dog from drafts.

In this case, you can get by with inexpensive roll heaters.

- Foamed polyethylene provides reliable wind protection and good thermal insulation already at a thickness of 4-6 millimeters. It is attached to the walls, floor and roof of the booth with the same stapler, after which it is again sheathed with any durable material. The crate is not needed: short self-tapping screws can be screwed directly through the insulation into the boards, so long as they do not stick out inside.

Useful: on sale you can find polyethylene foam with an adhesive layer. The method of fixing it is familiar to you if you have ever insulated plastic windows or steel doors with self-adhesive window insulation: after removing the protective glossy paper, the material is simply pressed against the surface. In this case, temporary fastening with a stapler is not necessary.

- Penofol - an advanced version of roll insulation. On one side of the polyethylene foam, aluminum foil is applied, which reflects infrared radiation. Fixed between the inner and outer walls of the booth, the material will further reduce heat loss.

Conclusion

As you can see, there are a lot of options. If you are still thinking about how to insulate a dog house, in the video presented in this article you will find Additional information on this topic. warm winters you and your pet!

Pavel Bondarenko, Donetsk.

With the onset of winter, many owners of dogs living in the yard of a private house come to the conclusion that it is necessary to additionally insulate their pet's home. Of course, the booth must initially be made in accordance with all the rules of "booth" architecture, that is, the design itself is made of solid and warm: the walls have a heat-insulating layer, the outer upholstery eliminates the presence of cracks, and so on. The most logical action in this case is to install a curtain that would close the hole in the booth. The curtain, which is absolutely not necessary in the warm season, turns out to be most welcome in winter. So I had a need to manufacture this, at first glance, a simple product.

There are probably few experts in the matter of making doghouse curtains. So I, not being one, decided to study the issue on the example of the experience of people who have succeeded in this business more than me and posted information about their products on the Internet. As a result of searching and getting acquainted with information on the topic, I realized that most users consider the curtain to be a very simple product that does not require special attention and description. Actually, a piece of some fabric unnecessary in the household, which is nailed on top of the manhole and cut along the vertical - this is a typical design. However, in practice, everything turned out to be not so simple.

At first I decided not to come up with anything particularly unique and, having found a suitable piece of a flannelette blanket, I made a curtain of the simplest design out of it.

What this product was, I will describe a little lower, first I will give the initial data, which determined the design and size of the curtain - these are the parameters of the booth manhole.

The manhole is a rectangular hole measuring 400 (width) X 450 (height) mm in the front wall of the booth. The manhole is shifted to the left side of the front wall and is located at a distance of 65 mm from the outer edge of the left wall of the booth and 540 mm from the outer edge of the right wall of the booth. The manhole has a threshold, so the lower edge of the manhole is located at a height of 115 mm from the lower edge of the front side of the booth. Along the perimeter of the manhole there is a cashing made of a rail 20 (thickness) X 28 (width) mm. Now directly description of the design of the curtain.

A piece of a flannelette blanket measuring 530x1240 mm and about 1.5 mm thick is doubled in length. The result was a two-layer blank with a width of 530 and a length of 620 mm. Along the length of the workpiece in the center of the canvas, a cut 520 mm long is made - the entrance. The cut is made in the direction of the inflection of the workpiece tissue and does not reach the inflection, respectively, by 100 mm. The upper part of the workpiece (above the cut, in the place of the inflection of the fabric) is sandwiched between two wooden slats 60 wide and 530 mm long. The thickness of the rails is 12 mm. The curtain is fastened with 2 self-tapping screws above the upper rail of the manhole trim using two wooden linings 12 mm thick to prevent deflection of the curtain fabric when touching the upper rail of the manhole trim. It is simpler - two linings must be placed under the structure at the attachment point so that the curtain fabric hangs freely down without touching the manhole trim. That is if you have cash. In the absence of such, it is clear that nothing needs to be laid, moreover, the lower rail of the structure, adjacent directly to the wall of the booth, should be as thin as possible to eliminate the appearance of a gap between the curtain and the wall of the booth. It may even make sense to exclude this rail from the design in general, but then the installation of the curtain will become more complicated and the curtain itself will lose its mobility and completeness of the structure. The height of the curtain is set in such a way that its lower edge is 50 mm below the upper edge of the manhole threshold.

I draw your attention to the fact that the material for the manufacture of curtains should be exactly a flannelette blanket or a fabric of similar parameters: on the one hand, the material is thick enough with satisfactory heat-insulating properties, on the other hand, it is soft. In this case, you can get minimal clearances around the perimeter of the curtain, even if you have a dog on a chain. By the way, when using it is not enough soft tissue and the absence of special measures to neutralize the action of the chain, this chain greatly complicates the work of the curtain, clinging to it and partially dragging it inside the booth, thus creating gaps incompatible with satisfactory thermal insulation.

The manufacture of the above curtain took quite a bit of time. Perhaps this is the main significant advantage of this design.

The product was installed and worked well for a while. The only thing that I immediately did not like was the presence of a gap between the shutter doors. However, immediately after installation, the gap was very small and, compared with the obvious general improvement in the thermal insulation of the booth - the hole is much larger than a small gap - could be considered an insignificant trifle. However, over time, this gap gradually increased. After some time, its size already called into question the effectiveness of this design. In addition, a flannelette blanket, even folded in half, does not inspire much confidence as a heat-insulating material. There is a desire to replace it with something denser and thicker, especially in frosts from 8 -10 ° C.

Nevertheless, such a simple curtain, despite its shortcomings, satisfactorily performed its functions, and its design and parameters were used by me as a guideline in the manufacture of a more advanced curtain design. The curtain was dismantled, having honestly worked for one season. This is what the fabric used in this curtain looks like.

The gap between the doors of a simple curtain for a booth

The gap between the flaps in the picture is slightly smaller than that formed on the real curtain during one season of operation and the shape of the hole is different, but still the photo allows you to get an idea of the product, albeit an approximate one.

A more solid curtain will be described later. But is it worth it to "bother" with its manufacture - decide for yourself. The simplest curtain that I talked about is already a good solution to the problem. Yes, there are small gaps around the perimeter, the wind blows on the sides, yes there is a gap in the center, but in general the device works satisfactorily. If you want to have a better thing and can spend a few evenings after work not talking to the TV, but tailoring, plumbing and carpentry - read the article below. So,

High quality dog kennel

To begin with, let's decide how a high-quality curtain should differ from the previously described simple design, which, despite its shortcomings, is a quite decent basic model, on the basis of which we will create our new product.

First of all, it is necessary to eliminate the static gap between the leaves in the center of the booth manhole and minimize the possibility of the appearance and subsequent increase of this gap.

Why can this gap increase during operation? The dog constantly pushes the fabric to the sides, the fabric is wrinkled, stretched and remains deformed. If the dog is powerful and wide enough, like mine, for example, and the coat is periodically wet from rain or snow, which is inevitable, the process of deformation of the curtain passes quite quickly. As a result, instead of an inconspicuous gap, we get a hole of significant size - in my case, something about 120 mm in the widest part - resembling an inverted U in shape.

How to deal with it. First of all, the curtain should not be made from one piece of fabric cut in the middle, but from two independent pieces connected into a single structure with an overlap, an overlap. In my curtain, the overlap is 50 mm. Enough, but you can do a little more. In this case, the fabric should be sufficiently rigid, that is, if possible, it should succumb to deformation as weakly as possible.

The weighting of the lower parts of the sashes has a very positive effect on reducing the gap in the center and in general on the work of the curtain. But more on that later.

What does static clearance mean? This is the gap when closing the curtain manually, when the flaps hang down freely, without catching on the threshold of the manhole or the chain that the dog is tied to. With a chain, of course.

It is much more difficult to deal with gaps that arise directly during the normal operation of the curtain. When testing experimental samples of curtains made of various materials, it turned out that it is often quite difficult to achieve a clear, high-quality closing of the manhole. The dog will not correct the stuck sash. Yes, and she breaks into the booth at different angles, from different directions and at different speeds. Again, the chain is stretched differently and pulled into the booth. All this leads to the fact that the quality of closing the curtain, that is, maintaining relatively the same and minimal gaps at each closing, strongly depends on how the dog enters the booth at one time or another.

This problem is solved in several ways, the first and simplest of which is the use of soft fabric for the manufacture of curtains, as in our basic model. Moreover, even if one or two wings are pulled into the booth by a chain or a dog, the gaps will be quite tolerable. In addition, soft shutters cannot get stuck, catching on the threshold of the booth, which easily happens with long (below the threshold) hard curtains and leads to the formation of a huge gap in the manhole zone. However, soft fabric is in most cases not the best thermal insulation and wind protection. Of course, we mean available materials - it is quite possible that you can find a soft fabric with all the necessary properties among high-tech modern products, but this is not our case.

The second way, which, in combination with the weighting of the lower edge of the shutters, allows you to achieve a clear closing of the curtain with minimal dependence on the actions of the dog and the presence of a chain, is to set it in height so that a gap of 15-20 mm is obtained between the lower edge of the curtain and the upper edge of the threshold of the booth . The shutter closes normally, but the presence of a significant gap calls into question the appropriateness of using this method. High-quality closing of the manhole with such a curtain device does not work - the gap cannot be called minimal. Nevertheless, I have met similar designs, however, without weighting the curtains, in practice. Even with gaps far exceeding 15-20 mm. I would characterize such an option as "better than nothing".

And finally, the third way. Separate sashes are made of dense fabric. The curtain is suspended as suggested for the second method, namely, 15-20 mm above the threshold of the booth. Four are sewn to the lower parts of the flaps - two for each flap, from the front and back sides of the flaps - flaps made of soft fabric. These valves close the gap between the threshold and the curtain.

This variant of the design of the curtains showed good quality of closing the manhole during operation with minimal dependence on the actions of the dog and the presence of a chain and was adopted as the main one for the manufacture of high-quality curtains.

The next step in finalizing the basic design will be to improve the thermal insulation and windproof properties of the product. In practice, I realized the improvement of these properties by replacing the curtain material and applying measures to eliminate side gaps.

Regarding the material, the following was done: instead of two layers of a flannelette blanket, he used four layers of woolen. The result fully met expectations - the design turned out to be solid, inspiring confidence.

Side gaps take place in the case when the curtain is attached only above the entrance to the booth, as is done in most cases in practice. In principle, in calm weather, these gaps may be absent or insignificant, but in the presence of wind, blowing into the booth is inevitable. In strong winds, due to significant fluctuations in the curtain, the entrance to the booth can periodically open almost completely. Improves the situation, but does not eliminate the problem of the weighting of the lower parts of the valves. The way to save the dog from blowing into the side cracks is very simple. The curtain is made with a certain margin in width and is nailed on the sides through a wooden lath with small nails to the wall of the booth.

Self-tapping screws can be used instead of nails. This is if the dog likes to tear off the slats between times. Well, or just for reliability.

And the last stage of refinement. A noticeable improvement in the quality of the work of the product can be achieved by applying the weighting of the lower edges of the valves. The weighting agents keep the sashes in tension, which contributes to a significant reduction in their deformation during operation and prevents the appearance of a gap between the sashes. The clarity of the manhole closing increases due to the increase in the closing speed and, as a result, the tendency of the leaves to catch on an obstacle, for example, a chain, and “hang” on it, leaving part of the manhole open, decreases. In fact, weighting leads to a noticeable decrease in the dependence of the curtain on how the dog entered or left the booth at the moment. However, as for the exit from the booth, the weighted curtains close in this case almost always equally well.

Structurally, the weighting agent is a set of steel plates 28x28x2 mm in size, sewn into the sash along that part of its lower edge, which is opposite the manhole. A set of plates, rather than a single steel strip or rod, is used to keep the sash flexible, which has a positive effect on the quality of the blind as a whole.

The photo shows the lower edge of the right sash with weights sewn in.

So, by deep modification of the basic curtain model, we got a product of the following design (the dimensions are indicated for the booth, the parameters of which are described in the first part of the article).

Two flaps measuring 675 (height) X 490 (width) mm are made of a woolen blanket. The sashes are four-layer, which provides good thermal insulation.

Each sash has two flaps in the lower part made of a bike measuring 270x140x1.5 mm.

Each sash has weights in the lower part from a set of steel plates 28x28x2 mm - 6 pcs. on each sash.

The sashes have a mutual overlap in width equal to 50 mm in the middle of the curtain.

The upper edges of the shutters are located on the same line and are clamped with the help of three self-tapping screws between two wooden slats measuring 530x60x12 mm so that the center of the curtain web - two wings folded overlapping - coincides with the centers of the rails.

This design is mounted above the manhole so that the center of the curtain coincides with the center of the manhole, and the distance between the lower edge of the curtain made of woolen material and the upper edge of the booth threshold is 15-20 mm. That is, the height adjustment of the installation is carried out with the bike valves raised up.

Between the lower mounting rail and the front wall of the booth there is an adjusting rail 12 mm thick to eliminate the grazing of the curtain by cashing the manhole.

The structure is attached to the wall of the booth with two self-tapping screws, the length of which, as far as I remember, is 70 mm.

The outer vertical sides of the curtain and the horizontal parts of the upper edge, which are not clamped by the fastening strips, are nailed to the booth wall with nails 20 mm long through a strip of plywood 4 mm thick and 20-25 mm wide.

The result is a design similar to the one shown in the photo:

Here are the product specifications:

1. good thermal insulation and wind protection (windproof curtain fabric, no gaps on the sides and top of the manhole);

2. closing the manhole while maintaining minimal gaps in the center and at the bottom of the manhole even when the dog is on a chain;