Vegetable fiber. What are fibers? Species and origin

The main substance that makes up natural fibers of animal origin (wool and silk) are animal fibrillar proteins synthesized in nature - keratin and fibroin, individual units of macromolecules of which consist of sets of residues of various -amino acids having the general formula

NH 2 –CH–COOH

They differ from each other in the chemical composition of the radical R.

Physico-chemical properties of keratin and fibroin, i.e. fibers of wool and silk, to a large extent depend on chemical composition radicals of their constituent -amino acids.

Having acid - UNSD- and basic -NH 2 - groups, keratin and fibroin have amphoteric properties, i.e. can react as acids and bases, and there are more acidic groups in fibroin molecules than in keratin. This explains their equal affinity for basic, neutral and acidic dyes.

Compared to cellulose, proteins are resistant to the action of weak mineral acids and organic medium concentrations. At normal temperatures (about 20°), mineral acids of medium concentration worsen their properties only with prolonged exposure. With an increase in temperature and concentration of acids, destruction occurs more intensively. In concentrated acid solutions, both keratin and fibroin are rapidly destroyed.

Proteins are not very resistant to the action of alkalis. Even weak solutions lead to swelling of keratin and fibroin and to significant structural changes in the latter. At the same time, the dyeability of wool and silk improves, and the mechanical properties deteriorate. When heated, even weak alkali solutions easily destroy keratin and fibroin. Concentrated alkali solutions easily destroy fibroin even at normal temperatures. Therefore, when finishing cloths made of wool and silk, only neutral detergents are used; in addition, the modes of processes must be strictly controlled.

When exposed to light, the process of oxidation of keratin and fibroin by atmospheric oxygen is activated in the same way as in cellulose. The lightfastness of keratin is higher than that of cellulose, while that of fibroin is lower. When heated, intensive deterioration of properties begins at temperatures above 170°C.

Keratin and fibroin have much better sorption properties than cellulose. This is facilitated by the presence of side chains in protein macromolecules.

wool fiber

Wool is a hair fiber of various animals: sheep, goats, camels, etc.

The industry mainly processes sheep's natural wool. Mixed with it, in a small amount, restored wool is used, obtained by developing woolen rags and rags, as well as factory wool, removed from the skins of slaughtered animals in the production of leather. Sheep natural wool makes up to 98% of the total. The rest falls on the share of camel and goat hair, goat down, etc. Wool fibers consist of three or two layers, depending on their type: scaly 1 , cortical 2 and core 3 (Fig. 6, a, b). The scaly layer of wool consists of thin horn-shaped plates of various sizes and shapes. It protects the cortical layer from harmful chemical and physical influences, and to a large extent ensures the rollability and sheen of the coat.

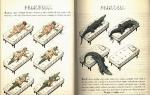

Rice. 6. Structure of wool fibers:

a) awns; b) fluff; c) longitudinal view and cross section: 1 - fluff;

2 - transitional hair; 3 - awns; 4 - dead hair

The cortical layer of wool consists of spindle-shaped cells and determines the main properties of the fiber - its strength, extensibility, elasticity, flexibility, softness. The cells of the cortical layer contain a pigment on which the natural color of the fiber depends.

The core layer of wool consists of loose cells and gaps filled with air. The dimensions of the core layer depending on the type of wool fibers may be different. This layer reduces thermal conductivity, reduces strength, flexibility, crimp and other properties.

Sheep wool fibers are divided into fluff, awn, transitional and dead hair (Fig. 6, in).

Down is the thinnest crimped fiber, the diameter of which is 14–30 μm, and the cross section is close to round (Fig. 6, b).

Outside, the fiber is covered with ring-shaped scales. 1 with uneven edges, and inside is filled with a cortical layer 2 . The latter consists of spindle-shaped fibrillar cells 80–90 µm long and 4–6 µm across. The cells are located along the axis of the fibers and are glued together by an intercellular substance, which, under chemical influences on the wool fiber, decomposes earlier than the keratin of spindle-shaped cells.

The awn is much thicker and coarser than the down, has almost no tortuosity, the diameter is 40–60 µm. In addition to lamellar scales 1 covering the spine from the outside, and the cortical layer 2 there is also a core layer along the entire length 3 , which consists of loose thin-walled cells filled with air bubbles (Fig. 6, a). The core layer, without increasing the strength, only contributes to increasing the thickness of the fiber, i.e. deterioration of its quality, increasing the stiffness of the hair.

Transitional hair occupies an intermediate position in thickness between down and awn and has a discontinuous core layer.

Dead hair is the coarsest non-crimped fiber with a diameter of 80 microns or more. This fiber is covered with large lamellar scales and has a narrow ring of the cortical layer and a very large core (up to 90% of the fiber diameter). The cross-sectional shape is most often flattened, irregular. Dead hair is a tough, brittle fiber with little strength and poor dyeability.

Wool, consisting mainly of fibers of one type (down or transitional hair), is called homogeneous, and containing fibers of all these types, heterogeneous. The more fluff and less dead hair in heterogeneous wool, the better its quality. Depending on the thickness of the fibers and uniformity, wool is divided into fine, semi-fine, semi-coarse and coarse.

Fine wool consists only of downy fibers, uniform in thickness, length, crimped, with a transverse size of 14–25 microns.

Semi-fine and semi-coarse wool consists of transitional and downy fibers. The average transverse size of semi-fine wool is 25-31 microns, semi-coarse 31-40 microns. The length of semi-fine and semi-coarse wool is somewhat longer than that of fine wool.

The heterogeneity of the coat consists of a mixture of down, transitional hair, awn and dead hair, it is not uniform in length and thickness. Depending on the average thickness, this wool is divided into semi-coarse and coarse. The average transverse size of heterogeneous semi-coarse wool is 24-38 microns, and coarse 38.1-45 microns and above.

The main properties of wool are determined by the properties of keratin. Wool fiber has high hygroscopicity (38-40%), low strength (relative breaking load 10-14 cN/tex), but wool materials are well formed and retain their original shape. When wool is burned in a flame, the fibers are sintered, forming black balls, while the smell of a burnt horn or feather is felt.

A feature of wool is its ability to felting, which is explained by the presence of a scaly layer on its surface, significant crimp, and softness of the fibers. Due to this property, rather dense fabrics, cloth, drapes, felt, as well as felt and felted products are produced from wool.

Wool fibers have an undulating crimp, characterized by the number of turns per 1 cm and the shape of the crimp. Fine wool has 4–12 or more twists per 1 cm of length, coarse wool is slightly twisted. Due to the natural crimp, wool is well twisted into yarn, which is used for the production of fabrics, knitted and non-woven materials.

Wool has low thermal conductivity, that is, good heat-shielding properties, which makes it indispensable in the production of coat, suit and dress fabrics and winter knitwear.

Silk is called thin long threads produced by the silk glands of the silkworm (silkworm) and wound around the cocoon.

Textile enterprises receive raw silk from cocoon primary processing plants, where the following processes are carried out: cocoon curing with steam or hot water in order to kill the silkworm pupa contained in the cocoon; steaming cocoons, i.e. treating them with hot water to dissolve sericin; unwinding of cocoons, where cocoon threads from 3–9 cocoons are simultaneously wound onto a reel. The resulting thread is called raw silk.

To  window thread (Fig. 7) consists of two elementary threads (silk) glued together with sericin, a natural adhesive produced by the silkworm. In the cross section, the elementary thread has an oval shape, its thickness along the entire length (500-900 mm) is uneven, and has a diameter of 15-17 microns.

window thread (Fig. 7) consists of two elementary threads (silk) glued together with sericin, a natural adhesive produced by the silkworm. In the cross section, the elementary thread has an oval shape, its thickness along the entire length (500-900 mm) is uneven, and has a diameter of 15-17 microns.

The main physical and mechanical properties of silk are determined by fibroin and are therefore similar to the properties of wool fibers. Threads have: elasticity, hygroscopicity, beautiful matte sheen. Materials made from natural silk have significant shrinkage. Unlike wool, silk is more durable (27–32 cN/tex), but less resistant to light. Lye is especially sensitive to the action of ultraviolet rays, so the service life of natural silk products in sunlight decreases dramatically. Natural silk is widely used in the production of dress fabrics and piece goods (head scarves, scarves, scarves), sewing, embroidery threads.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

educational institution

Minsk State Regional Lyceum

abstract

in chemistry on the topic:

natural fibers

Prepared by a student of 11 "B" class

Denisenko Georgy

Introduction

1. Natural animal fibers

2. Natural fibers of mineral origin

3. Natural fibers plant origin

Introduction

Fibers consist of unspun strands of material or long, thin strands of thread. Fibers are used in nature by both animals and plants to hold tissues (biological).

natural fibers- these are fibers that exist in nature in finished form, they are formed without the direct participation of man. This group includes fibers of plant, animal and mineral origin.

The main features for classification are: the chemical composition of the fibers and the area of their origin.

1. Natural fibers of animal origin

Silk- consists of fiber of animal (protein) origin. Silk threads are obtained from the cocoons of silkworm caterpillars. The silk group includes such fabrics as veil, chiffon, crepe de chine, satin chesucha, crepe, crepe georgette, toile, fai, taffeta, brocade, foulard, etc. Traditionally, silk is considered one of the most expensive types of fabric. Products made of silk fabric are very light, durable, beautiful. They have a pleasant shine, well regulate body temperature. The disadvantages of silk include the fact that the fabric is very wrinkled and sensitive to ultraviolet rays. Often, another kind of fiber is added to natural silk fiber to obtain new interesting textures and various spectacular weaves. It is worth noting that artificial and synthetic silk fabrics are also produced.

Wool- natural fibers of animal (protein) origin. Animal hair is used as a raw material - sheep wool, camel wool, llama wool, rabbit wool, etc. The group of woolen fabrics includes: twill, cloth, tweed, boston, carpetcott, cheviot, duvetin, etc. The wool of various animals differs in quality, properties and applications. the only general characteristics all types of wool - this is an exceptional quality to keep warm. A significant amount of wool (94-96%) for the textile industry is supplied by sheep breeding. Natural wool fabrics are soft, elastic, light, breathable. The thickness of the fabrics can be different, there are both thick and thin woolen fabrics. Wool fabrics practically do not wrinkle.

mi natural fibermineral origin

Asbestos(Greek indestructible) - the collective name for a group of fine-fibred minerals from the silicate class. In nature, these are aggregates with a spatial structure in the form of the thinnest flexible fibers. Used in the most various areas, for example in construction, the automotive industry and rocket science. According to the chemical composition, asbestos is hydrous silicates of magnesium, iron, calcium and occurs in rocks in the form of veins and veins.

Natural plant fibers

natural fiber vegetable animal

Cellulose is the main constituent of plant fibers. This solid, hardly soluble substance, consists of C6H10O5 units. In addition to cellulose, plant fibers contain waxes, fats, proteins, dyes, etc.

Cotton is a natural fiber of plant origin. Cotton is produced from the fibers of the seeds of cotton plants. Based on cotton, satin, batiste, gauze, chintz, denim, flannel, canine, teak, calico, voile, percale, nansuk, organdy, pique, poplin, veil and other fabrics are produced.

The advantages of cotton fabric are: strength, high wear resistance, alkali resistance and elasticity. The fabric is warm, soft and pleasant to the touch, absorbs moisture well, does not electrify. The disadvantage of the fabric is high wrinkling due to a small proportion of elastic deformation. Sometimes viscose is added to the fabrics of the cotton group, and then an amazing sheen or pattern appears on their matte surface.

Linen is a natural and environmentally friendly fiber of plant origin. The raw material for the production of flax is the stem of a herbaceous plant of the same name. Linen fabrics are hygienic, durable, soft to the touch, with good moisture and breathable properties. However, linen fabrics, due to their slight extensibility and low elasticity, are extremely wrinkled and poorly ironed, and also shrink quite a lot when washed. Most often, linen products are produced in a natural color (from gray to beige). They have a nice sheen.

Jute has long been used to make rope and burlap, and as a natural base for carpets and linoleum. Jute fiber is obtained from a plant of the same name, which grows mainly in India and Bangladesh. Woven jute flooring is softer than coconut or sisal, so it is only suitable for areas where there is no heavy traffic, such as bedrooms. Here, the texture of jute products will be an additional advantage - it is pleasant to walk on them barefoot.

Coconut fiber (coir) obtained from coconut nuts. Durable and resilient floor coverings are made from coir - carpets, mats and door mats. Coconut fiber is extremely durable, but it is prickly and difficult to dye.

Hemp(hemp stalks fiber) is extremely durable, does not rot and is not afraid of salt water, and also does not fade or deteriorate in bright light. Hemp grown for the textile industry does not contain active narcotic components. It grows beautifully and does not need chemical protection or top dressing. They make hemp and coarse cloth from it.

Combined with other, softer natural fibers, hemp is the raw material for light and comfortable fabrics that can be used in a wide variety of ways.

Rattan- a liana that grows in Southeast Asia. Baskets, mats and chair seats are woven from rattan fibers.

Sisal has incredible strength and durability. This coarse natural fiber is obtained from agave leaves. Sisal mats, mats and rugs can be used in high traffic areas. The material is softer than coconut fiber, but coarser than wool. Sisal does not have water-repellent properties, water stains remain on it. But it is easy to dye, and the choice of colors here is greater than in the case of other natural fibers.

Hosted on Allbest.ru

...Similar Documents

Natural fibers of animal, mineral and vegetable origin. Classification of natural fibers. Use of animal hair. Hydrous silicates of magnesium, iron and calcium. The chemical composition of the fibers and the region of their origin.

abstract, added 11/23/2012

Characteristics of synthetic fibers. Positive aspects and disadvantages of capron, lavsan, spandex. Classification of natural fibers. Description of cotton and wool. Man-made fibers of organic and inorganic origin.

presentation, added 05/06/2015

Silk is a natural elementary thread of animal origin. Acquaintance with the history of silk production, the properties of the thread. Description of the main areas of application of natural silk materials, as well as modern prospects for the use of these fabrics.

abstract, added 05/09/2015

Properties of casein fiber: breaking length, specific gravity, moisture absorption, electrification. drying technology. Influence of its additives on the quality of wool. Features of dyeing artificial fibers. Examples of its application in the textile industry.

presentation, added 12/03/2014

Physical and chemical properties of cellulose. Sulfite, soda and sulfate cooking methods. Obtaining artificial fibers: viscose, acetate, copper-ammonia silk and artificial wool. Manufacture of paper, plastics, film and photographic films.

presentation, added 12/25/2013

Types of artificial fibers, their properties and practical use. Viscose, copper-ammonia and acetate fibers, cellulose as the starting material for their production. Improvement of consumer properties of yarn through the use of chemical fibers.

term paper, added 12/02/2011

The study of the history of the origin of oil. Study physical properties and chemical composition. Scheme of a modern oil refinery. Fractions after distillation of crude oil. Analysis of production, transportation, processing, storage. Oil products.

presentation, added 03/11/2014

Technology of obtaining fabrics. The main features of determining the direction of the main thread. The structure, composition and properties of tissues. Methods for processing long fibers of wool, cotton and natural silk. Basic standards for determining the grade of fabrics.

test added 04/04/2010

Dependence of the physical-mechanical and strength properties of paper on the interaction between the fibers. Addition of recycled fiber, wood pulp, fillers to increase dry strength. The value of the number of hydroxyl bonds.

presentation, added 10/23/2013

Classification of chemical fibers. Properties and qualities of their artificial varieties: viscose and acetate fibers. Polyamide and polyester analogues. Scope of nylon, lavsan, polyester and polyacrylonitrile fibers, acrylic yarn.

Natural fibers (cotton, flax and others) are the main raw materials for the domestic textile industry. They are made from various natural products.

Origin of natural fibers

Raw materials, we repeat, are obtained from various products. Depending on the material, the fibers differ from each other in quality, appearance, and other characteristics. At the same time, there is a category of the most commonly used raw materials. In the textile industry, they are in the first place in terms of application. Their characteristics depend on the characteristics of the crops from which the raw materials are made. In addition, natural fibers of animal origin are used. These include, for example, wool, silk.

Properties of natural fibers

As mentioned above, the characteristics of raw materials depend on the characteristics of the products from which they are obtained. The most common are cotton fibers. They are obtained from a specially grown crop. Cotton is cultivated in more than 50 countries. It is a perennial thermophilic culture. The plant looks like a shrub, the height of which is from one meter or more. Every year, after flowering, fruits are formed on the culture. They are presented in the form of boxes with seeds. They are covered by 7 to 15 thousand hairs. They are cotton fibres. The length of the hairs is in the range of 12-60 mm. The longer they are, the better the yarn and fabrics. Textiles are produced from natural fibers, which can be easily dyed and processed. As a rule, the feedstock for industry has a white or brown color. Meanwhile, at present, cultivation technologies can produce colored

Bast raw materials

natural fibers obtained from the stems and leaves of various crops. These, for example, include jute, flax, nettle and others. Linen is considered the thinnest, most flexible and softest. From them, yarn is first created. It is subsequently used to produce durable and soft tissues. Linen is of several types. The length of the fibers depends on the height of the stem. The most valuable in the industrial sense is fiber flax. Its stems can reach a height of 0.8-1 m. Low-quality gives curly flax.

The process of obtaining raw materials

Ripe flax stalks are pulled out along with the roots. This is necessary to maintain the length of the fibers. This process is called "pulling". Previously, it was done manually. Currently, special combines are working in the fields. On flax threshers, the stalks are freed from seeds. The resulting straw is soaked in special pools or other bodies of water. Part of the flax stem is the bast. It is located under the bark. In the form of thin ligaments, it contains fibers. Their isolation from the stems is carried out at special plants. The enterprises use a special technology for separating the fibers from the bark and their subsequent processing. The soaked stems are dried. Then they are crushed and shaken. After that, the natural fibers are bleached because they have a light yellow, turning into a steel color.

Other cultures

The fibers of other plants are coarse and hard. They are mainly used in the manufacture of ropes, canvas, burlap, ropes, etc. For example, hemp fiber - natural material and similar to linen in many ways. However, it is not as soft. In this regard, it is used, as a rule, in the production of canvas, burlap, twine, ropes. Bast is obtained not only from the stems. Leaves can also be used as a raw material, for example.

Silk

For its production, fibers are used, which are obtained from silkworm cocoons. They are formed at a certain stage of caterpillar development. They weave a cocoon, which is an oblong egg-shaped shell. It consists of the finest fiber, which is interwoven in 40-50 layers. The thread is formed as follows. There are two holes on the head just below the caterpillar's mouth. A thick liquid is released from them, which freezes in the air. Her education is ongoing. As a result, 2 strands are formed, which are glued together with sericin. This is a special substance that is also secreted by the caterpillar. As a result, one thread is created, which goes to weave a cocoon.

Industrial processing

The color of the cocoon depends on the type of silkworm. They are reddish-yellow, white, yellowish. Other types of silkworms are also bred, which weave pale pink, green, blue cocoons. However, it should be said that the natural color of the threads is not stable. In addition, colored fibers can subsequently complicate the dyeing process. Before further use in industry, cocoons are bleached.

To obtain high quality fibers, cocoons are treated with steam or hot air. The pupae in them are killed, and to prevent decomposition, they are dried. If this is not done, then the insect will turn into a butterfly and begin to get out of the cocoon. Accordingly, it will be subjected to mechanical damage, which negatively affects the quality of the threads. Before winding the fibers, the cocoons are placed in pools filled with hot water. Then they are treated with steam and alkaline solutions. This is necessary to soften the sericin. One cocoon gives about 400-1200 m of thread. However, it is very thin. Therefore, fibers from 3 to 30 cocoons are combined into one.

Wool

What other natural fibers are used in industry? Animals give industry and wool. It is also processed to obtain threads. Wool has a variety of qualities and characteristics. Differences are present in the fibers of one animal different types. For example, from sheep's wool, the one that is obtained from fine-fleeced and semi-fine-fleeced sheep is of great value. In the process of cutting, the hairline is removed in a continuous layer. Fleece varies in quality. The most valuable fibers are located on the back, abdomen, shoulder blades. The hair on the legs and back is coarse. However, down is considered the highest quality and most valuable. Its fibers are flexible, elastic and thin. The quality of wool largely depends on the time of cutting. The fibers obtained in the spring will be softer. They have a lot of fluff. In autumn it is almost absent in wool. Therefore, these fibers are rigid. However, the autumn wool is cleaner than the spring one. Among the fibers are distinguished:

- The awn is a thick fiber.

- Transitional hair. According to its characteristics, it occupies an intermediate place between the awn and down.

- Dead hair. It is presented in the form of rigid and low-strength fibers.

Processing features

The properties of the yarn will depend on the quality of the fibers used to make it. The best varieties are made from fluff. The quality of fibers is determined not only by their strength, softness, fineness, but also by their length. She, in turn, will depend on the breed of sheep. The length of wool can reach 180-200 mm. The raw material is always exposed primary processing. It includes sorting, cleaning of garbage (clods of earth, burdock, etc.). Then detachment, loosening is performed. After that, the wool is washed and dried. Sorting is done manually. Fleece is laid out on special tables. Here it is divided into parts. In accordance with certain quality standards, the wool in the batch is selected. Washing is carried out with special compositions with the addition of detergents. This is necessary to remove fat particles.

Chemical raw materials

With the development of technology, it became possible to produce artificial and The main reason for the use of chemistry in the production of raw materials is the high demand for textiles. The available resources could not meet the needs of the population. Obtaining artificial raw materials is carried out using These include, in particular, cotton, wood and other cellulose, milk proteins, etc. These substances are subjected to chemical treatment with nitrogen, sulfuric, acetic acids, acetone, caustic soda and so on. As a result, viscose, nitro silk, acetate, copper-ammonia silk are obtained.

Synthetic raw materials

They are obtained by processing different products. Among them: oil and coal, associated and natural gases, agricultural waste and pulp and paper production. High molecular weight resins are isolated from substances. They act as the starting material for the production of synthetic raw materials. Processing and processing of resins is carried out according to a special, rather complex technology. Among the most widely used are nylon, lavsan, kapron, milan, PVC and others. Chemical raw materials are given certain qualitative characteristics in advance. In particular, it is durable, resistant to moisture, paint, etc.

mixed raw materials

The chemical and natural fibers mentioned above are homogeneous materials. Meanwhile, today the mixing of raw materials is gaining more and more popularity. The introduction of new technologies in textile production provides ample opportunities for obtaining a huge range of yarn. Natural fibers can be mixed both with each other and with artificial and synthetic materials. For example, they combine nylon and linen, nylon and wool. To obtain semi-silk and semi-woolen fabrics, not only a mixture of fibers is used. New technologies of weaving are actively applied. In particular, when creating a canvas, the warp threads are the yarn of some fibers, and the weft - of others.

Conclusion

The textile industry is considered one of the largest manufacturing sectors. High-quality raw materials must be used to manufacture demanded products. It must comply with state standards, be subjected to careful processing. This is important for fibers of any origin, including chemical ones. It should be noted that the industry is constantly introducing Hi-tech production. This, in turn, requires the supply of new types of raw materials.

We get the first idea of what fibers are at school in biology lessons. In a broad sense, expressing a more general essence in relation to the particular, this concept represents a class of materials consisting of threads or cells.

Muscle fiber is a structural unit of muscle tissue, which is a multinucleated cell, which consists of a large number other cells, which may be of plant, animal, mineral or artificial origin.

Come from Old Slavonic

The origin of the word "fiber" is associated with the Old Slavonic "Vlakno". This word exists in modern Bulgarian, Czech, Slovak, Serbian languages. With a slight phonetic difference, it is found in Polish - wlOkno. There is a related concept in ancient Indian: valkas, which means "bast".

In Russian, this lexical unit has undergone changes as a result of vowel alternation: OLO-LA. Since "fiber" is a dictionary word, its spelling must be memorized.

To get an idea of what fibers are as a material classification, let's take a closer look at their types.

Cotton and bast

Vegetable fibers include bast and cotton. Thin threads of cotton cover cotton seeds. They consist mainly (94%) of cellulose, and the rest is water, pectins, fat-containing, waxy, ash substances (mineral nutrients taken by the plant from the soil).

You can understand what cotton fibers are by examining them under a microscope. We will see a flat twisted ribbon with a tubule filled with air.

These threads are hygroscopic, heat-resistant, have high strength in relation to the action of alkalis. If cotton is set on fire, the smell of burnt paper will be felt.

Negative qualities include low elasticity and instability to the action of acids.

Bast fibers are obtained from a flax stem. They are elongated cells with pointed ends. In cross section they have the shape of a pentahedron. A larger percentage of the composition is cellulose (80%), and the remaining percentages are fatty, coloring, waxy mineral impurities and lignin. The presence of lignin gives increased strength. High thermal conductivity makes linen always cool to the touch.

Animal fibers

Goat, sheep, camel and other wool, as well as natural silk, are animal fibers consisting of three layers: the outer scaly, the main cortical layer and the core, which is located in the center of the thread.

There are 4 types of wool fibers:

- twisted thin - fluff;

- intermediate hair - the average between down and awn;

- rough and little crimped - awn;

- short brittle fiber - dead hair.

Depending on the types of thread, types of wool are also distinguished: from fine, which is used to make high-quality woolen products, to coarse, used to make cloth and felt. Wool is able to retain heat and is hygroscopic. When it burns, the smell of a burnt feather appears.

The lightest natural fiber is silk. It is obtained from the cocoon of the silkworm caterpillar.

Two proteins - fibroin and sericin - are part of the cocoon thread. Natural silk is characterized by softness, smoothness, high hygroscopicity, low wrinkling. The disadvantages are the high shrinkage of the twisted thread and low heat resistance. Silk is the most valuable raw material for the manufacture of light summer clothing.

Synthetic threads

What is the origin, you can understand by studying their nature. They are produced through chemical synthesis from monomers, that is, low molecular weight substances. As a result, the raw materials for nylon, lavsan, acrylic, crimplene are formed, are the products of processing of coal, oil, gas. These fiber threads have high strength, low creasing and shrinkage, but are not hygroscopic.

The variety of properties of polymers, the ability to vary them, as well as the availability of raw materials are incentives for the development of the production of synthetic fibers.

Chemical fibers

They are obtained by processing such synthetic substances as polyamides, polyesters, as well as natural materials: cellulose, proteins, casein and others. The raw materials for obtaining these fibers are cotton waste, various metals, glass, oil products, and coal.

Viscose is one of the first fibers of chemical origin to be commercialized. It is obtained by treating wood pulp with chemicals.

One of the main disadvantages of viscose fiber is high creasing. To reduce this quality, it is subjected to a process of chemical modification. The result is a polynose fiber resembling fine-staple cotton.

Lesson plan on technology. Section "Elements of materials science". Class 6. Theme "Natural fibers of animal origin. Properties of fabrics." Contains a presentation for the lesson and applications with instruction cards for the practical part of the lesson and additional materials for the lesson.

Download:

Preview:

To use the preview of presentations, create an account for yourself ( account) Google and sign in: https://accounts.google.com

Slides captions:

Natural fibers of animal origin The presentation for the lesson was prepared by the teacher of technology Syplivchak A.S. MBU lyceum 60 g.o. Tolyatti

Merino Fine Wool

distinguished by excellent wool. From one sheep of this breed it is possible to get up to 10 kilograms of wool in one haircut. To date, the best breed of sheep is MERINO.

Memorize new words! Wool is animal hair. Fleece is wool taken from sheep. Down is the thinnest, softest, crimped fiber. The awn (transitional hair) is a thicker, stiffer and less crimped fiber. Dead hair is a low-strength and very hard fiber.

One of the most ancient wool products that have survived to this day are carpets. The oldest known carpet was found in Altai, its age is more than two and a half thousand years.

Ukok Plateau, Altai

The Pazyryk carpet (5th-3rd century BC) is kept in the Hermitage.

the composition is framed by a border with 24 figures of grazing spotted fallow deer with characteristic broad-bladed horns.

Physical education 1. Starting position - sitting, hands on the belt. 1–2. Head turn to the right. Starting position. 3–4. Head turn to the left. Starting position. 5–6. Gently tilt your head back. Starting position. Tilt your head forward. Repeat 4-6 times. The pace is slow. 2. Starting position - sitting, arms raised up. 1–2. Squeeze your hands into a fist. Unclench the brushes. Repeat 6-8 times, then relax your arms down and shake your hands. The pace is average.

Gymnastics for the eyes Blink quickly, close your eyes and sit quietly, slowly counting to 5. Repeat 4-5 times. Close your eyes tightly (count to 3), open your eyes and look into the distance (count to 5). Repeat 4-5 times. Pull out right hand forward. Follow with your eyes, without turning your head, the slow movements of the index finger of the outstretched hand to the left and right, up and down. Repeat 4-5 times. Look at the index finger of the outstretched hand at the expense of 1-4, then look into the distance at the expense of 1-6. Repeat 4-5 times. At an average pace, do 3-4 circular motion eyes to the right side, the same amount to the left side. Relaxing eye muscles, look into the distance at a score of 1-6. Repeat 1-2 times.

Silk, or rather, silk thread, is a product of the silkworm. Thin threads obtained from the cocoons of the silkworm caterpillar, an insect known in China since time immemorial

Silkworm caterpillar

Memorize new words! Natural silk - thin threads that are obtained from the cocoons of the silkworm caterpillar Raw silk - a material obtained by joint unwinding of several cocoons. Grena - silkworm eggs.

Laboratory research Features fibers" 1) Consider appearance samples, determine which of them has a shiny surface, and which has a matte surface; 2) Compare to the touch the softness and smoothness of each fabric sample; 3) Pull two threads from each piece of fabric. Set fire to one of the threads. Observe the combustion process; 4) Break another thread and consider the appearance of its breakage; 5) After considering the breakage of the thread, determine the crimp of the fibers; 6) Summarize the findings. Determine the type of fabric for each sample from the table.

Characteristics Cotton Linen Woolen Natural silk Surface texture Rough, matt Smooth, shiny Rough, matt Smooth, shiny Softness Soft Rigid Medium hardness Soft Crimping Slightly crimped Straight Curved Straight Type of thread breakage Fleece Tassel of straight fibers Tassel with divergent crimped fibers Bound mass of fibers Burning , the smell of burnt paper Gray ash, the smell of burnt paper Black ball, the smell of burnt feathers Black ball, the smell of burnt feathers

"Determination of tissue properties" 1. Determine the wrinkling of tissues: a) squeeze the flap in your hand for several seconds; b) put it on the table and leave for a few minutes; c) determine by eye the appearance of the fabric: strongly wrinkled, wrinkled and indelible. 2. Determine the drapeability of fabrics: a) collect the upper cut of the flap along the length on a thread; b) carefully examine the formed folds. 3. Determine the shedding of fabrics: a) take a piece of fabric measuring 3x5 cm; b) with a hand needle, remove one thread from the sample, two threads together, three threads together, and so on; c) the fabric is considered to be easily frayed if five threads are easily removed together, three or four threads are of medium fraying, one or two threads are not fraying. 4. Determine the wettability of fabrics: a) wet a piece of fabric in a cup of water; b) Observe how quickly the water is absorbed.

Preview:

Appendix 3

Instruction card number 1

"Distinguishing Features of Fibers"

Equipment and materials: tissue samples, magnifying glass, tweezers, thick needle, matches.

1) Consider the appearance of the samples, determine which of them has a shiny surface, and which has a matte surface;

2) Compare to the touch the softness and smoothness of each fabric sample;

3) Pull two threads from each piece of fabric. Set fire to one of the threads (burning teacher). Observe the combustion process;

4) Break another thread and consider the appearance of its breakage;

5) After considering the breakage of the thread, determine the crimp of the fibers;

6) Summarize the findings. Determine the type of fabric for each sample from the table.

surface texture | Rough, matte, smooth, shiny |

Softness | Soft Rigid medium hardness |

crimp | Little twisted Direct Collection |

Type of thread breakage | Fleece, brush made of straight fibers, tassel with diverging twisted fibers, bound mass of fibers |

Combustion | Gray ash, the smell of burnt paper, black ball, smell of burnt feather |

signs | Sample #1 | Sample #2 | Sample #3 | Sample #4 |

surface texture | ||||

Softness | ||||

crimp | ||||

Type of thread breakage | ||||

Combustion |

Preview:

Annex 2

The legend of silk

For the first time, the secret of making silk was discovered in China five thousand years ago. An ancient legend says that once 14-year-old Xi Ling Chi, the wife of the third emperor of China, Huang Di, who was also called " yellow emperor”, in the garden of the palace, under the crown of a mulberry tree, she drank tea and a silkworm cocoon fell into her cup of tea from a tree. The young empress and her maids were extremely surprised to see how the cocoon began to unfold in hot water, releasing a thin silk thread. Intrigued, the girl began to watch how the cocoon unfolded. Xi Ling Chi was so impressed by the beauty and strength of the silk thread that she collected thousands of cocoons and wove the emperor's clothes from them. So the tiny silkworm butterfly gave silk to all mankind, and the empress, in gratitude for such a valuable gift, was elevated to the rank of a deity.

For more than three thousand years, China kept the secret of this amazing material, and any attempt to take silkworm cocoons out of the country was punishable by death. According to legend, only in 550 AD, two wandering monks in their staffs hollowed out small holes, where they hid silkworm larvae. So silk came to Byzantium.

Silk appeared in India thanks to the cunning of the Indian king, who wooed a Chinese princess and demanded mulberry seeds and silkworm larvae as a dowry. Unable to refuse the groom, the princess hid the seeds and larvae in her hair and took them out of the country.

The great demand for silk from Europe was the beginning of the great Silk Road. Silk, which appeared in the Roman Empire, was so expensive that it was worth its weight in gold and was often used as a currency in trade, and only very rich people were allowed to wear it. Emperor Julius Caesar demonstrated his power by ordering a precious silk fabric to be pulled over the awnings during his triumphant entry into Rome.

In Europe, flowing and delicate to the touch silk clothes were valued not only for their beauty and durability, but also for other things no less. important quality- insects did not start in it, which plagued even noble persons at that time, who did not sin with excessive cleanliness.

In the 15th century in France, the fashion for silk underwear was first introduced by the notorious Marquise de Pompadour. And to this day, this “light as a cloud” and “transparent as ice” fabric is considered an attribute of good taste and luxury.

Preview:

Appendix 4

Instruction card number 2

"Determination of tissue properties"

Equipment and materials: tissue samples, a cup of water, a thick needle, a magnifying glass, a needle and thread.

Work order:

1. Determine the wrinkling of fabrics:

a) squeeze the flap in your hand for a few seconds;

b) put it on the table and leave for a few minutes;

c) determine by eye the appearance of the fabric: strongly wrinkled, wrinkled and indelible.

2. Determine the drape of fabrics:

3. Determine the wetting of fabrics:

a) wet a piece of cloth in a cup of water;

b) Observe how quickly the water is absorbed.

4. Determine the shedding of fabrics:

Properties | Sample #1 | Sample #2 | Sample #3 | Sample #4 |

Wrinkle | ||||

Drapeability | ||||

Wetting | ||||

shattering |

Preview:

Attachment 1

It is interesting!

One of the most ancient wool products that have survived to this day are carpets. The oldest known carpet was found in Altai, its age is more than two and a half thousand years. It should be noted that the technology for the production of handmade carpets has not changed much over the past millennia.

The famous Pazyryk carpet (5-4 centuries BC) was discovered during archaeological excavations of the Pazyryk-5 mound. It is stored in the Hermitage..(slide)

The Ukok Plateau is located in the permafrost zone, which ensured the good preservation of the carpet and other artifacts of the burial mound. “The artistic design of the carpet is distinguished by its richness and variety of motifs. The central field is occupied by an ornament of 24 cruciform figures, each of which, according to Russian scientists, represents 4 schematized lotus buds. Although if you trace the Turkic carpets, it becomes clear that, in fact, these are stylized images of tamga. This composition is framed by a border depicting eagle griffins, then comes a border with 24 figures of grazing spotted fallow deer with characteristic broad-bladed horns. On the widest strip there are figures of mounted and dismounted riders. The combination of bright yellow, blue, red colors created a spectacular colorful range. The number of warp threads is about 120 per 1 dm square. The carpet is made with a symmetrical double chord knot, also called Turkish. There are 3,600 knots tied on one square decimeter, and there are more than 1,250,000 of them in the entire carpet. The carpet has a fairly high density. The dimensions of the carpet are 1.89 x 2.00 meters. The time spent on making such a carpet by modern craftsmen is estimated at one and a half years. The most laborious part seems to be that part of the wide frame of the carpet field, on which horsemen are depicted, alternating every other with footmen, and the footmen hold the bridles of horses in their hands. Felt saddles are visible on the backs of the horses, each of which differs from the others in its shape and color. On these felt saddles, ancient Turkic tamgas are also depicted. In addition, images of a leopard and winged horses are also imprinted on the carpet.

Preview:

Technology Lesson Plan

Teacher: Syplivchak A.S.

Subject: technology

Grade: 6

Section: Elements of materials science

Topic: Natural fibers of animal origin. tissue properties.

Objectives: Educational - to familiarize students with natural animal fibers. To teach how to identify fabrics from these fibers, to acquaint students with the properties of woolen and silk fabrics, to teach how to use knowledge about these properties in the manufacture of garments.

Developing - to develop spatial representation, logical thinking, independent work skills with visual aids.

Educational - to cultivate aesthetic taste, attentiveness, accuracy, a sense of partnership.

Type of lesson: study and primary consolidation of new knowledge.

Type of lesson: lesson - practice.

Equipment and materials: Fibers collection, Wool and Silk collections, magnifying glass, tweezers, needle, fireproof cup, matches, fabric samples, textbook, workbook, computer, projector, screen.

Teaching methods: demonstration, verbal (conversation on questions, story), visual, laboratory research work.

Lesson plan:

I Organizational part (3-5 min)

II Repetition of the material covered (5-7 min)

III Theoretical part (learning new material) (25-30 min)

1) a story about natural fibers of animal origin, the history of making fabrics from wool and silk.

2) an explanation of the properties of woolen and linen fabrics.

IV Practical part (primary consolidation of knowledge). (30 minutes)

V Consolidation of the studied material (primary test of knowledge acquisition)

1) filling in the table.

VI Debriefing (10 min)

1) analysis of the work performed (control and self-control of knowledge);

2) knowledge assessment;

3) generalization of the obtained information.

During the classes:

I. Organizational part

1) checking readiness for the lesson

2) appointment of attendants, checking absent

3) message of the topic of the lesson

II. Repetition of the material covered

Let's remember what fibers we have already studied? What two groups are they divided into?(Students answer).

Natural and chemical, natural plant and animal origin

What are the properties of natural plant fibers?(Students answer)

Good hygienic, heat-shielding properties, strength, light resistance, high hygroscopicity, heat protection, easy care for products made from natural fiber fabrics.

III. Theoretical part (learning new material)

The topic of the lesson is announced, and presentation slides are shown, the relevance of this topic and its connection with life are substantiated. ( slide 1)

(Teacher's word) From the first days, a person is faced with various tissues. Your undershirts and diapers were made of cotton, in cold weather a woolen blanket warmed you, how nice it is to wear a cotton T-shirt, a linen shirt, and warm woolen socks on a hot summer day.

Now you can choose your own fabric for a dress or suit. And in order not to be mistaken, you need to know the composition of the fabric and properties. If you pull the thread out of the fabric, split it, you can see that it consists of tiny thin and short hairs - fibers. These fibers (wool - in woolen fabric, hairs - in cotton) are called spinning fibers. Threads and yarn are obtained from fibers, and fabrics are obtained from threads and yarn.

Fibers are divided into natural - those that are donated by nature itself (woolen, silk, linen, cotton) and chemical, which are obtained as a result of chemical processes. ( slide 2)

Today at the lesson we will get acquainted withnatural fibers of animal origin.Woolen and silk. Fabrics made from such fibers are environmentally friendly and therefore represent a certain value for a person and have a positive effect on his health.

Each meter of textile material produced today bears the memory and knowledge accumulated and accumulated over centuries and millennia, during which man has been engaged in one of the most ancient technologies.

Wool one of the oldest fibers known to mankind. The inhabitants of the ancient settlement on the territory of modern Switzerland raised sheep. The earliest date associated with sheep breeding and wool production, confirmed by excavations, corresponds to 4000 BC. In the Euphrates Valley (Ancient Mesopotamia), sheep were bred, wool was spun, and primitive fabrics were woven. In ancient Babylon, woolen fabrics were made, and on the territory of the country of UR (mentioned in the Bible), not far from the Persian Gulf, archaeologists unearthed an ancient mosaic depicting sheep breeding. Since ancient times, people have used mainly sheep's wool for spinning. However, other species were also used: goat, dog, cow, camel, rabbit, etc.(slide 3)

Thanks to selection, already two thousand years ago, several types of domestic sheep could be distinguished: fine-fleeced, coarse-wooled and fat-tailed.(Students look at collections)Depending on the thickness of the fibers that form the sheep's hairline, the wool is divided into fine, semi-fine, semi-coarse and coarse. Today there are about 40 breeds of sheep in the world, producing more than 200 various types wool. Fine wool merino sheep give the best wool.(slides 4,5)

Production of wool for the textile industry

Fine-wool sheep breeding in the Middle Ages was actively developed in Spain. Today, the best Merino sheep are bred in New Zealand and Australia. These sheep are distinguished by excellent wool. This coat is very long and thin. From one sheep of this breed it is possible to get up to 10 kilograms of wool in one haircut. ( slide 6 ) They shear sheep with special tools. ( slide 7)

Wool is the hair of sheep, goats, camels and other animals. The bulk of the wool (94-96%) for the textile industry is supplied by sheep breeding. The softest, silkiest wool the highest category obtained from the sheared wool of small lambs. Wool must have a certain length. Wool reaches its normal length in sheep of most breeds at the age of one year, so it is customary to shear sheep once a year in the spring with the onset of warm, stable weather. Wool sheared in one layer from a sheep is called fleece. (Slide 8) (Writing definitions in a notebook)

Sheep wool consists of four types of fibers:

down - a very fine, crimped, soft and durable fiber, round in cross section

transitional hair - a thicker and coarser fiber than down

awn - a fiber that is stiffer than the transitional hair

dead hair - very thick in diameter and coarse non-crimped fiber, covered with large lamellar scales.

From the wool of other animals, goat mohair is widely used, camel hair is used for the manufacture of outerwear and blankets, and highly elastic cushioning materials are obtained from horse hair.

After shearing, the wool will go through many stages of processing before it turns into a warm, noble, woolen thread. Since the sheep are grazing outdoors, the wool is heavily soiled, so the fibers first go through the primary processing.(Slide 9)

First, the sheared wool is sorted and sorted according to strength, fineness, waviness, color; shake - loosen and remove clogging impurities; then there is a thorough washing of the wool from dirt and sand with soap and soda; then dried in tumble dryers.

Preparatory production (Work according to the schemes in the collection at the workplaces of students simultaneously with the explanation of the teacher).

Carding (carding shop) - obtaining a fibrous tape. On carding machines, it is passed between two surfaces covered with thin metal needles.

Tape shop - alignment of the direction of the wool fibers in the tape, stretching, reducing the tape in thickness (thinness) on the tape machine

Roving shop – twisting and drawing the fiber sliver into a roving.

Spinning - drawing and twisting the roving into wool yarn on a spinning machine and winding in the form of cobs. Thicker and coarser yarn is obtained from short woolen fibers, and thin, even, smooth yarn is obtained from long ones. Yarn is made here.

(Showing the main products of the spinning process. Collection. Writing the scheme in a notebook).

Wool fibers have the following properties : have high hygroscopicity, i.e. well absorb moisture, resistant to sun exposure. Wool is considered the warmest fiber. Woolen fabrics get dirty a little and do not wrinkle too much. They have good hygienic properties, in clothes made of such fabrics it is comfortable, the body "breathes".

Woolen fibers are used to make dresses, suits and coats. Woolen fabrics go on sale under the following names: drape, cloth, gabardine, cashmere, etc. ( slide 10)

To check the wool fiber, you need to set fire to a piece of fabric. During combustion, the wool fiber is sintered, the resulting sintered ball is easily rubbed with fingers. In the process of burning, the smell of burnt feather is felt. So you can determine whether the fabric is clean in front of you or artificial.

The Pazyryk carpet (5th-3rd century BC) is kept in the Hermitage.

Appendix 1 "It's interesting!" ( slide 11,12,13,14)

Physical education:(Slide 15,16)

1. Exercise to improve cerebral circulation. Starting position - sitting, hands on the belt. 1–2. Head turn to the right. Starting position. 3–4. Head turn to the left. Starting position. 5–6. Gently tilt your head back. Starting position. Tilt your head forward. Repeat 4-6 times. The pace is slow.

2. Exercise to relieve fatigue from the small muscles of the hand. Starting position - sitting, arms raised up. 1–2. Squeeze your hands into a fist. Unclench the brushes. Repeat 6-8 times, then relax your arms down and shake your hands. The pace is average.

3. Exercise to relieve fatigue from the muscles of the body. Starting position - stand legs apart, hands behind the head. 1–2. Raise your right hand on the belt, left hand on the belt. 3–4. Right hand on shoulder, left hand on shoulder. 5–6. Right hand up, left hand up. 7–8. Make two claps with your hands above your head. 9–10. Put your left hand on your shoulder, right hand on your shoulder. 11–12. left hand on the belt, right hand on the belt. 13–14. Make two hand claps on the thighs. Repeat 4-6 times. The pace is slow the first time, medium the second and third times, fast the fourth and fifth times, and slow the sixth time.

Gymnastics for the eyes:

1. Blink quickly, close your eyes and sit quietly, slowly counting to 5. Repeat 4-5 times.

3. Stretch your right hand forward. Follow with your eyes, without turning your head, the slow movements of the index finger of the outstretched hand to the left and right, up and down. Repeat 4-5 times.

4. Look at the index finger of the outstretched hand at the expense of 1-4, then look into the distance at the expense of 1-6. Repeat 4-5 times.

5. At an average pace, do 3-4 circular movements with your eyes to the right side, the same amount to the left side. After relaxing the eye muscles, look into the distance at the expense of 1-6. Repeat 1-2 times.

Silk, to be more precise, silk thread is a product of the silkworm activity. Thin threads obtained from the cocoons of the silkworm caterpillar, an insect known in China since time immemorial (according to Confucius, from the 3rd millennium BC).(slide 17,18)

The technology for making silk fabrics definitely comes either from China or other countries. Far East and her birth corresponds to ~3000 BC. There is a legend that says that the Chinese Empress Xen-Ling-Chi (2600 BC) was the first to discover this wonderful fiber. She accidentally dropped the cocoon into the hot water and saw silk threads detach from the softened cocoon. The Empress came up with the idea that the thread with which the caterpillar wraps itself can be unwound and weaved a cloth from it. Which she did. The fabric turned out to be wonderfully thin, light, practical, beautiful. This is how the ancient culture of sericulture was born, based on the vital activity of the silkworm, which feeds on the leaves of the white mulberry (mulberry).

The Chinese brought the culture and production of silk and silk fabrics to perfection and around 1400 BC. silk fabrics different kind and clothing made from them became the subject of common consumption in these countries. In China, there was at that time a tax on the use of silk products.

The silkworm is in the full sense of the word a domestic animal.(slide 19)

In nature wild species This butterfly is no longer found.Silkworm caterpillars hatch from eggs (grain) at a temperature of 23–25°C.(slide 20)

It takes 8-10 days for the eggs to develop, after which small, only about 3 mm long, larvae are born. They are dark brown in color and covered with tufts. long hair. Silkworm larvae feed exclusively on mulberry (mulberry) leaves, they eat the leaves non-stop day and night, which is why they grow very quickly.Caterpillars grow very fast, but their skin does not grow. Therefore, when the skin becomes very small, silkworm caterpillars molt.

During its life, the silkworm caterpillar molts 4 times. After the fourth molt, the caterpillar already looks quite impressive: its body length is about 8 cm, its thickness is about 1 cm, and its weight is 3–5 g.(slide 21)

Her body is now almost naked and painted whitish, pearly or ivory. But the main thing is a small tubercle under the lower lip, from which a sticky substance oozes, which, upon contact with air, immediately freezes and turns into silk thread.

Even the smallest caterpillar that has just emerged from the egg can already secrete a thin thread. Every day the caterpillar is preparing more and more for pupation. The weight of the cocoon together with the chrysalis is from 1 to 4 g. It takes about 4 days to make a cocoon.After about 20 days, the chrysalis turns into a butterfly.(slide 22)

The silkworm butterfly is inconspicuous, the color of its plump hairy body is white with a light cream pattern, or dark grayish brown. The wingspan of the silkworm is about 4.5 cm, but these butterflies cannot fly. They have lost this ability. Silkworm butterflies live for about 12 days.The female lays eggs from 300 to 800 pieces. This process takes her 5-6 days. Silkworm eggs are very small, there are about 1500 of them in one gram. After 10-20 days after laying, the butterflies die.

But not every caterpillar that weaves a cocoon can turn into a butterfly and live its 20 days. Most of the cocoons go to receive raw silk - material receivedat joint unwinding of several cocoons.(slides 23,24,25,26)

To get 1 kg of raw silk, you need about a thousand caterpillars that eat 60 kg of mulberry leaves in a month and a half - these are three mulberry trees!Cocoons are kept in a special oven for 2-2.5 hours at a temperature of about 100 ° C. This kills the caterpillars that are in cocoons and makes it easier to unwind. The length of the cocoon thread reaches from 800 m to 3 km.

Silk fibers have the following properties: they have good hygroscopicity and breathability, less resistant to sunlight than other natural fibers. Silk burns just like wool. Products made of natural silk are very pleasant to wear due to their good hygienic properties.

This is how people get silk thread, from which they then sew beautiful pajamas, bathrobes, dresses, underwear and bed linen and other clothes.(slide 27,28)

IV. Practical part (primary consolidation of knowledge)

Remind about safety rules when working with a needle and scissors.

Group work in their places, two in each group.Laboratory research:(slides 29,30,31)

Instruction card No. 1 "Distinctive features of fibers"

Instruction card No. 2 "Determination of tissue properties"

V. Consolidation of the studied material. Filling in the table.(Students fill in the tables indicated in the instruction cards). Summarizing the data obtained and formulating the conclusions of each group.

VI. Summarizing:

1) analysis of work performed(the teacher evaluates the correctness of filling in the tables).

Self-control of knowledge: at the end of the lesson, students put leaflets with their names in boxes with marks "3", "4", "5".

Peer review: each group evaluates each other.(swap completed tables and check with the correct answers)

2) knowledge assessment.

3) generalization of the information received(the teacher makes the necessary comments, grades).

Conclusion. (Teacher's word) We studied fabrics made from natural fibers of plant and animal origin: cotton, linen, wool and silk. These fabrics are environmentally friendly and have a beneficial effect on human health, but their production is laborious and expensive. Therefore, such fabrics should be treated sparingly and with care.